-

Km9+100 Vo Van Kiet, Van Tuong commune, Quang Ngai province

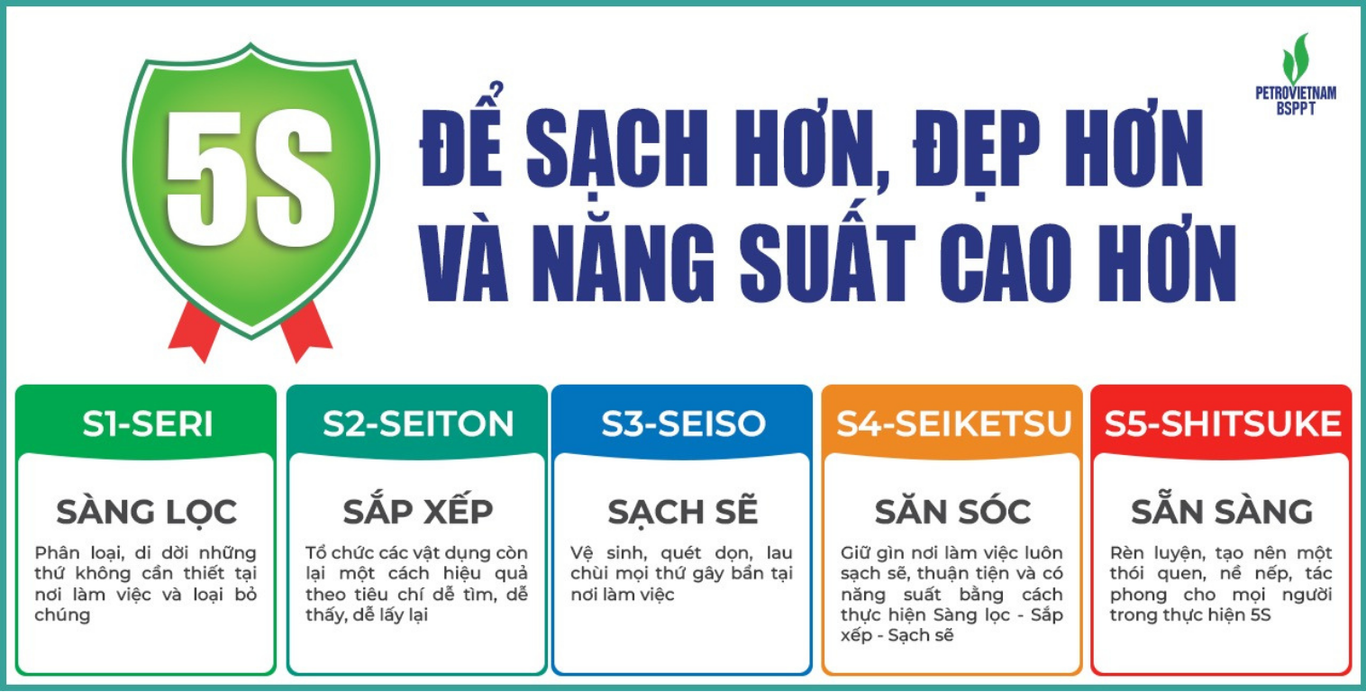

IMPLEMENTING 5S IN PRODUCTION AT BSPPT

In the manufacturing sector, optimizing the workspace, increasing productivity, and ensuring product quality are key factors determining a company’s success. At BSPPT, we apply the 5S management method to improve the working environment, minimize waste, and enhance production efficiency.

1. Seiri

Sorting helps categorize and eliminate unnecessary items in the workplace, keeping only essential tools, materials, and equipment. This not only optimizes space but also reduces occupational safety risks and improves production efficiency.

2. Seiton

After sorting, all items, equipment, and materials must be organized systematically according to the principles: Easy to Find – Easy to See – Easy to Take – Easy to Check – Easy to Return. Proper arrangement helps reduce search time, minimize errors, and ensure smooth production processes.

3. Seiso

Maintaining cleanliness in the production area is crucial for ensuring product quality and protecting workers’ health. BSPPT encourages employees to regularly inspect, clean machinery, equipment, and workspaces to maintain the best working conditions.

4. Seiketsu

After implementing the first three steps, BSPPT focuses on sustaining and standardizing these activities by developing clear work processes. We continuously train employees and conduct periodic inspections to ensure a clean, organized, and efficient work environment.

5. Shitsuke

Discipline is essential for maintaining and developing the 5S culture. BSPPT encourages employees to form habits of adhering to 5S standards, thereby enhancing their sense of responsibility and continuous improvement mindset.

Benefits of Implementing 5S at BSPPT

- Increased Labor Productivity: Reduces time spent searching for tools and materials, allowing production to proceed quickly and efficiently.

- Improved Working Environment: A clean and organized workplace enhances employee morale and motivation.

- Ensured Workplace Safety: Minimizes risks of occupational accidents caused by clutter, dust, and improper arrangements.

- Enhanced Product Quality: Strict control from raw materials to finished products helps reduce defects and improve product quality.

Implementing 5S not only helps BSPPT optimize production operations but also lays a solid foundation for adopting other advanced management standards such as Kaizen and ISO. We believe that with the commitment of all employees, BSPPT will continue to grow sustainably and strengthen its competitive advantage in the market.